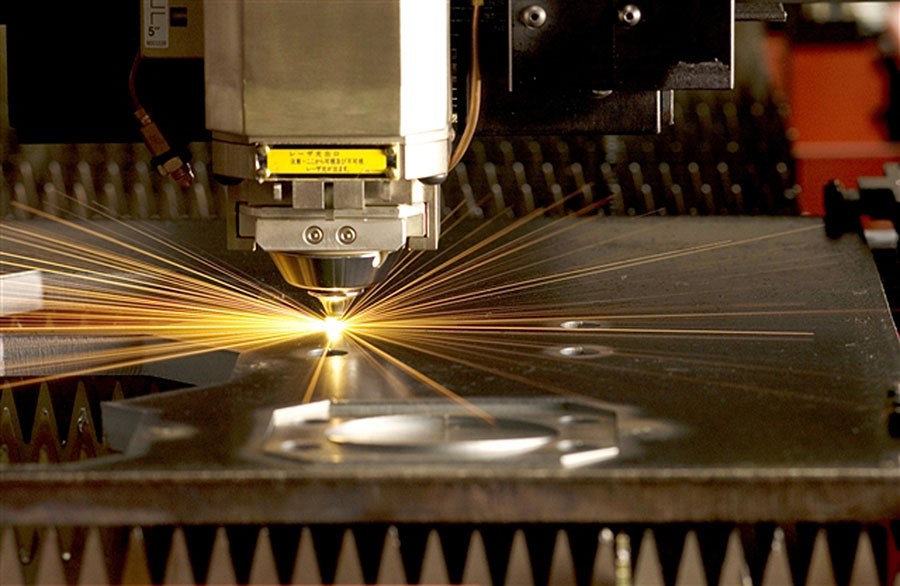

FoxFab has chosen a one-kilowatt (1kW) fiber laser cutting machine with two 5-foot by 10-foot auto exchange tables and a 3-axis cut head, which is enough power to cut up to 1/2″ inch steel with a 50 square foot dimensional capability per table. This allows us to match the most common material thicknesses and size demands found throughout many modern industries. Fiber lasers have a tremendous advantage over other cutting options such as Plasma, CO2, and Waterjet in that they are faster, more reliable, and lower-maintenance.

Flat Laser Cutting

Flat Laser Cutting

Rapid Prototypes. High-Volume Production Runs. Functional Art.

Custom Tooling And Die Sets. Limitless Possibilities.

HOW CREATIVE IS YOUR NEXT PROJECT?

Superior Cut Quality

Outperforms other cutting options in speed, efficiency, and throughput capacity.

Highly Reflective Materials

Cut aluminum, copper, brass, and even certain glass /mirror sheets

Two 5 Foot X 10 Foot Tables

Auto exchange capability means no waiting between cutting two sheets

1kW Of Cutting Power

Enough power to cut 1/2`` steel or 1/8`` aluminum; easily upgradeable

Advanced Nesting Software

Reduced material waste lowers overall product costs for customers

Low Maintenance

Minimal required routine maintenance maximizes machine up-time